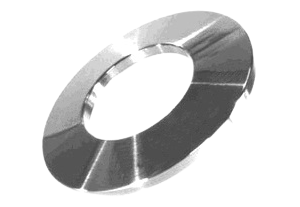

Disc Spring

What is a Disc Spring Washer ?

A Disc Spring Washer, also known as a Belleville Washer, is a type of washer with a conical, disc-like shape that functions as a spring. It is designed to provide high load-bearing capacity, absorb shocks, and maintain consistent pressure in mechanical assemblies, especially in situations where space is limited.

Disc Spring manufacturer :

We are Disc Spring manufacturer upto the following capacity :

● Thickness : Up to 20 mm.

● Outer Diameters : Up to 400 mm.

● Inner Diameters : As per Drawing / Data.

● Height : As per Drawing / Data.

● Raw-material Grades used : Spring Steels as per Indian standard – BS:970 EN-42, BS:970 EN-45, BS:970 EN-47, 50Cr.V4, 50Cr.4V2, 51Cr.V4, 50Cr.MoV4, 50Si7, 55Si7, 60Si7, SUP-9, SUP-9A, SAE-5160 etc. and others similar Foreign Grades JIS, ASTM etc.

● Disc Spring manufacturing process :

1. Material selection : Choosing the appropriate material (steel, stainless steel, etc.).

2. Cutting : Cutting the raw material to the desired size and shape.

3. Forming : Shaping the disc spring using stamping, pressing, or hydraulic forming.

4. Heat treatment : Heat treatment (tempering, quenching) to enhance the mechanical properties.

5. Surface finishing : Applying coatings or surface treatments for corrosion resistance and durability.

6. Testing and quality control : Performing load-deflection tests, fatigue tests, and visual inspections.

7. Packaging and delivery : Final packaging and shipping.

Disc Spring uses / application :

Disc Springs (Belleville Washers) are widely used across different industries due to their ability to provide high load-bearing capacity, absorb shocks, and maintain consistent pressure or preload in compact spaces. Below are some of the primary uses of Disc Springs :

● Used in vibration and shock absorption : Automotive suspensions, industrial machinery, aerospace.

● Used in preload and tension maintenance : Bolted joints and fasteners, Pipe flanges, Pressure systems, Compensation for wear and thermal expansion, Heavy machinery, Load balancing, Uniform pressure distribution, Hydraulic systems, Pressure relief and safety, Electrical and electronic systems, Connectors, Switches and relays, Suspension systems, Railways, Automotive clutches, Braking systems, Precision and measuring instruments, Mining equipment, Construction equipment, Seal and gasket applications, Flange seals, Load and pressure regulation, Pressure regulating devices, Fuel injectors.

Disc Spring DIN 2093 :

Disc Spring – DIN 2093 is a German standard that specifies the design, materials, and performance characteristics for Disc Springs (also known as Belleville washers). Disc springs designed to this standard are commonly used in applications requiring high load-bearing capacity and consistent spring performance in a compact form.

Key aspects of Disc Springs DIN 2093 (Belleville Washer) :

1. Geometry and Dimensions :

● Outer diameter (OD) : The total diameter of the Disc Spring.

● Inner diameter (ID) : The hole in the center of the Disc Spring, typically designed to fit around a bolt or shaft.

● Thickness (t) : The thickness of the spring at the thickest part of the cone.

● Free height (h0) : The height of the Disc Spring in its uncompressed state.

● Spring deflection : The amount by which the Disc Spring deflects under a given load. This property defines how much the spring can compress under a load and is essential for its performance.

2. Material specifications : The materials used for DIN 2093 Disc Springs are critical for their strength, fatigue resistance, and durability. Common materials include :

● Spring steel (e.g., 65Mn, 60Si2MnA) : Offers a good balance of strength, flexibility, and fatigue resistance.

● Stainless steel (e.g., AISI 301, AISI 304, AISI 316) : Used for corrosion-resistant applications.

● Alloy steel : For high-strength applications. Materials should meet the mechanical properties specified by the standard, such as tensile strength, yield strength, and hardness.

3. Load deflection characteristics :

● Load Capacity : DIN 2093 defines the load-bearing capacity of the Disc Spring for specific dimensions. It helps ensure that the spring can withstand the required loads in dynamic and static applications.

● Spring rate : This is the rate at which the spring deflects under load (force per unit of deflection). The spring rate depends on the material, the thickness of the disc, and the design.

● Deflection : The deflection (compression) of the Disc Spring under a load is important for applications requiring shock absorption or preload maintenance.

4. Performance in various environments : Disc Springs conforming to DIN 2093 are designed to handle varying environmental conditions, such as :

● Temperature fluctuations : The materials must retain their mechanical properties even at extreme temperatures.

● Corrosion resistance : Stainless steel options offer resistance to corrosion in environments where moisture or chemicals may be present.

● Vibration and dynamic loads : The springs should perform reliably under fluctuating loads and vibrations.

5. Manufacturing and quality control :

● Disc Springs must be manufactured with high precision to meet the required specifications and tolerances outlined in DIN 2093.

● Quality control tests include load-deflection tests, fatigue tests, and visual inspections to ensure the springs meet the standard’s mechanical and performance characteristics.

6. Summary of DIN 2093 Disc Spring characteristics :

● Geometry : Defined by the outer diameter, inner diameter, thickness, free height, and deflection.

● Materials : Typically made from high-quality spring steel, stainless steel, or alloy steel.

● Load deflection : The spring deflection under load is a critical property, and DIN 2093 defines the maximum loads and deflections allowed for each spring.

● Fatigue resistance : Designed for long service life and resistance to fatigue under cyclic loads.

● Stacking : Options for series or parallel stacking to modify load-bearing capacities.

● Applications : Automotive, aerospace, industrial machinery, hydraulic systems, and electrical applications.

7. Conclusion : Disc Spring (Belleville Washer) DIN 2093 provides an important standard for the manufacturing of Disc Springs, ensuring that they are reliable, durable, and suitable for a wide range of applications. If you’re looking to manufacture or source Disc Springs, following the DIN 2093 specifications will ensure consistency in quality and performance, especially in industries requiring high load-bearing capacities and resistance to fatigue.